קישורים

צור קשר

זמני פעילות:

ימים א’-ה’ בין השעות 08:00 ל-17:00

Save time and reduce the chance of production errors by using barcodes to automatically process multiple jobs at the touch of a button.

DataLink supports any combination of RIP software & printer in addition to included Cutting Master 4 and Graphtec Pro Studio software.

The CE7000 detects barcode-linked cutting data from the operator’s PC or USB flash memory, opens the correct file, sets the cutting conditions, and starts cutting automatically.

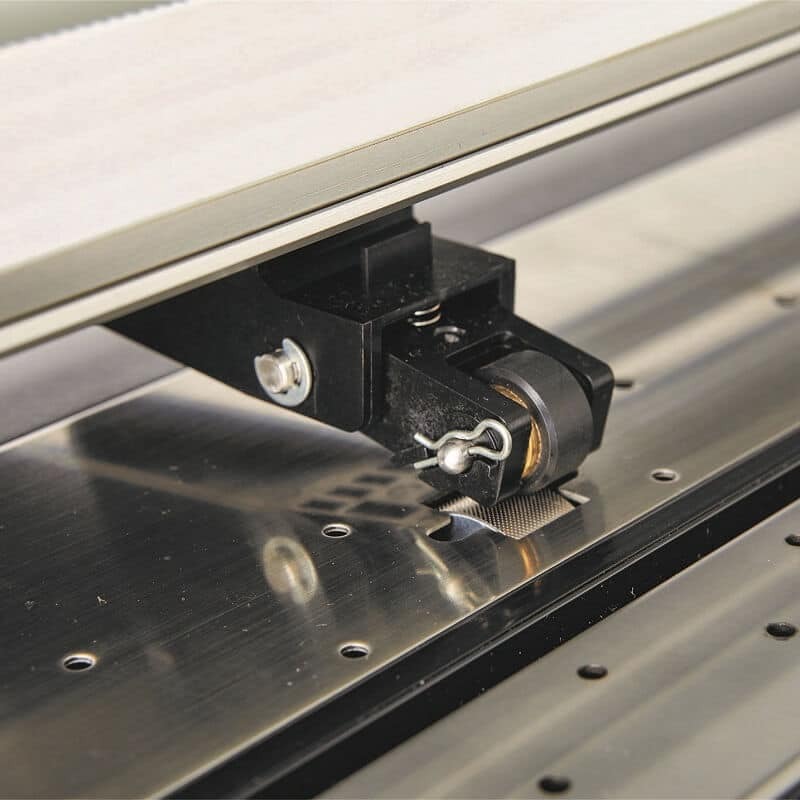

Separate tool positions for contour and die-cutting ensure the longevity of your blades and cutting strip when creating decals and graphics that are effortlessly popped out of sheet and roll media.

Improved ARMS for high precision cutting (ARMS 8.0)

The Advanced Registration Mark Sensing system delivers precise Print & Cut results by using sensors to detect registration marks and perform axis alignment. Countless efficiency-boosting features improve productivity for Print & Cut applications such as stickers and decals. Barcodes may now be generated and printed as part of the design which creates a hand’s free operation. The reading of Registration marks is faster increasing productivity.

A network connection is now possible through a network interface enabling the use of TCP/IP protocols to transfer cut data.

USB Offline Operation

A new secondary USB port has been added for placing thumb drives so jobs can be uploaded and cut without the need of a computer. Select barcode function or select file directly from the thumb drive.

(The USB memory format only supports FAT32. Please note that NTFS and exFAT are not supported.)

With maximum cutting force 4.41N (450gf) and maximum cutting speed 1000 mm/s, it enables to cut various media with high productivity.

Cutting performance that guarantees accurate 5m length cutting.

The media stocker helps stabilize the feeding of media. By adjusting the pressure of the middle push roller to the media in three levels, it prevents media floating.

In addition, by using an optional special basket, stability in long cuts can be achieved.

The 3.7 inch LCD display and easy-to-use control panel support 10 languages.

Barcode data management allows cutting different data sequentially by detecting the “Start Mark” of the new Barcode. Sequential Print & Cut process with roll-media is now available.

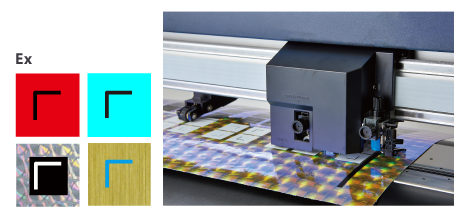

A wide variety of media types including holographic paper and reflective sheets are now compatible due to improvements of the ARMS sensor algorithm.

The sensor may not be able to read certain combinations of specialty media and colored marks.

Using the plug-in software Cutting Master 4, Adobe Illustrator crop marks will be available.

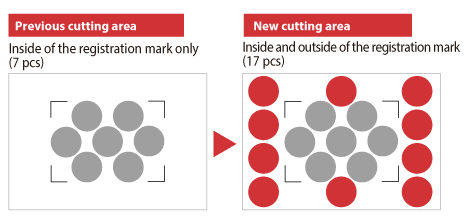

The expanded cutting area to include objects outside of the area enclosed by registration marks. Production efficiency is enhanced by reducing media waste.

| Configuration | Grit rolling type |

|---|---|

| Drive method | Digital servo drive |

| Max. cutting area (W x L) | 1372 mm x 50 m |

| Cutting area of guaranteed accuracy | 1250mm × 2m (1250mm × 5m) |

| Min. mountable media width | 50mm |

| Max. mountable media width | 1372mm (54inch) |

| Mountable roll media mass | 5 kg |

| Number of push rollers | 2 rollers |

| Max. cutting speed | 1000mm/s at 45° direction |

| Acceleration | 13.9m/s² at 45° direction |

| Cutting force | Max. 4.41N (450gf) |

| Mechanical resolution | 0.005mm |

| Programmable resolution | GP-GL:0.1/0.05/0.025/0.01mm HP-GL™ (*2):0.025mm |

| Repeatability | Max. 0.1 mm in plot up to 2 m (Excluding media expansion and contraction) |

| Minimum character size | Approx. 5 mm alphanumeric (varies depending on character font and media) |

| Mountable number of tools | 1 tool |

| Blade types | Supersteel |

| Pen types | Oil-based ballpoint pen, Water-based fiber-tip pen |

| Media types | Up to 0.25mm thickness Marking film (PVC / fluorescence / reflection), polyester film (With specified conditions) |

| Interface | USB 2.0 (Full Speed), Ethernet 10BASE-T/100BASE-TX |

| Buffer memory | 2MB |

| Command sets | GP-GL / HP-GL™ (Set by command or auto-detect) (*2) |

| Display | Graphic type LCD with back-light (240dots x 128dots), supports 10 languages |

| Power source | 100V to 240V AC, 200V to 240V AC, 50 / 60 Hz |

| Power consumption | Up to 100W |

| Operating environment | 10 to 35 ºC, 35 to 75 % R.H. (non-condensing) |

| Guaranteed accuracy environment | 16 to 32 ºC, 35 to 70 % R.H. (non-condensing) |

| External dimensions (W x D x H) | 1704×811×1215 mm (1704×1148×1215 mm)(*3) |

| Weight | 51kg (54.9kg) (approx. Includes stand and/or basket) |

| Compatible OS | Windows 10/8.1/7 Mac OS X 10.6 ~ 10.11 / macOS 10.12 ~ 10.15 (Graphtec Studio: 10.6 – 10.15, Cutting Master 4: 10.7 – 10.15) |

זמני פעילות:

ימים א’-ה’ בין השעות 08:00 ל-17:00